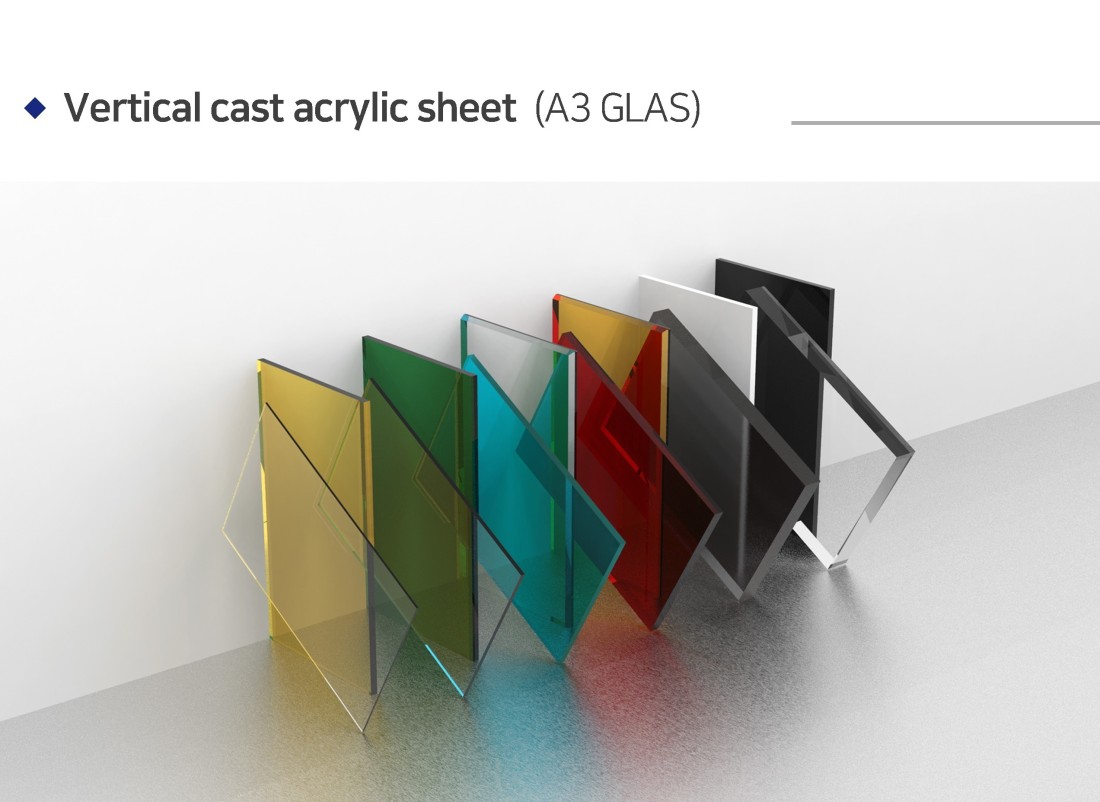

A3 GLAS

This acrylic is produced by transparent liquid, MMA with the casting method, before undergoing curing and heat treatment to produce a liquid in a vertical direction.

Similar to horizontal cast acrylic, transparent liquid, MMA is combined with a solidification catalyst and then injected between glass molds according to specifications before curing and undergoing medium temperature heat treatment using a water bath and high temperature heat treatment using a steam dryer. For some low-quality vertical cast acrylics, the second high-temperature steam drying process is omitted, and most of the domestic vertical cast acrylic plants are often small in size, so the quality largely differs between manufacturing plants.

Most factories manufacture vertical cast acrylic by mixing recycled scrap liquid, which lowers the strength and transparency when compared to cast acrylic made from 100% virgin material, and such a vertical manufacturing process cause severe thickness variation

Although our vertical cast acrylic (A3GLAS) also combines recycled liquid with a virgin liquid like other vertical cast acrylic, we are proud that the ratio of the recycled liquid is significantly lower than that of other manufacturers. We manufacture our acrylic using the latest scrap grinder and liquid filtering equipment. Therefore, the recycled liquid has higher quality and we also supply our recycled liquid separately to other cast acrylic factories. Furthermore, the secondary steam solidification heat treatment facility has also been updated to enable the production of high-quality, uniform quality and good strength acrylic.

▣ Specifications

| Thickness | Size | Color |

| 1.3mm ~ 30mm | 840X1740mm 910X1810mm 1040X1510mm 1150X1460mm 1240X1510mm 1240X1840mm 1240X2440mm | Clear, Colored |

| Customized size and color can be provided on request | ||