ADEX

PVC foam board is a type of plastic panel that is made by an extrusion machine that foams PVC (polyvinyl chloride) using a calendering method.

A large Korean company first released this PVC foam board under the name Foamex. Since many customers associated the product with this name, the PVC foam board was soon renamed Foamex. It is similar to the transparent tape called scotch tape made by 3M.

Several factors determine the quality of the PVC foam board, but some of the most important factors are as follows.

▣ Level of extrusion line

Similar to how rice cake is chewier and more delicious when it comes from the right mill, it is difficult to create a good surface, tight thickness tolerances, and consistently clean side quality during CNC machining with an inexpensive foam line.

All of ADEX’s PVC foam board is produced by Germany’s and Austria’s most famous foam extrusion lines exceeding 2.5 billion won per extruder, Germany's (KRAUSS-MAFFEI, BATTENFELD-CINCINATI) and Austria's (THEYSOHN) lines. There are a total of 7 machines estimated at over 17 billion won. For an inexpensive imported pvc foam board extruder with poor foaming quality, it is less than 100 million won per machine.

▣ Specific gravity of PVC foam board

PVC foam board is made by foaming raw PVC resin. In order for manufacturers to reduce the production cost, they have to foam the PVC as much as they can so that they can make cheap PVC foam board. When the specific gravity is low, the sheets will foam a lot. However, the durability becomes lower and thus they can easily break. This creates various problems when bending and assembling. For example, even the thickness tolerances can become inconsistent.

Don't rely on the specific gravity that the manufacturer gives you. Instead, compare the weight difference between the same sizes and same number of sheets. The heavy sheet is a PVC foam board with a high specific gravity. However, in addition to virgin PVC resin and additives for foaming, products that have increased weight due to the higher proportion of inexpensive stone powder components such as CACO3 (calcium carbonate) can cause even more problems during processing.

▣ Whether the raw PVC resin is virgin

ADEX’s PVC foam board contains more than 80% PVC resin (100% virgin PVC resin is used) and a catalyst and additives for foaming of 15%. In addition, the content of CACO3 is controlled to less than 5%.

If you think this content ratio doesn’t come in contact with your skin, check the following with your PVC foam sheet suppliers and ask them for official certificates.

Do you use only virgin, non-recycled, PVC resin?

How much is the content ratio of CACO3 controlled?

You can check why the quality of ADEX’s PVC foam board is so much better than that of other companies.

▣ Manufacturer of extrusion production line for each thickness of ADEX's PVC foam board

1MM ~ 5MM:

(Germany BATTENFELD-CINCINATI) https://www.battenfeld-cincinnati.com

8MM ~ 10MM:

(Germany KRAUSS-MAFFEI) https://www.kraussmaffei.com

12MM ~ 30MM:

(Austria THEYSOHN) https://www.theysohn.com

▣ Specifications

▣ Thickness / Specific gravity

| Thickness | Specific gravity |

| 1mm ~ 3mm | 0.70~0.92g/cbcm |

| 4mm ~ 10mm | 0.63~0.70g/cbcm |

| 11mm ~ 30mm | 0.55~0.63g/cbcm |

| Customized specific gravity can be provided on request | |

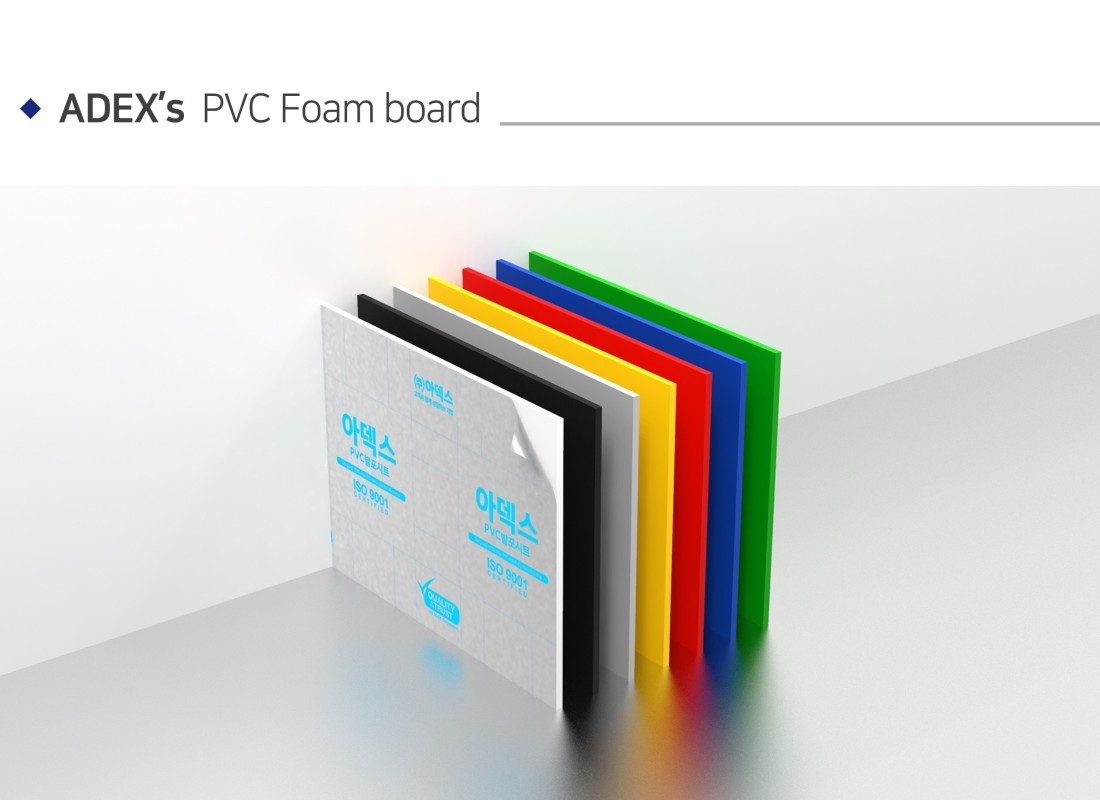

▣ Size / Color

| Size | Color |

| 915x1820mm 1220x2440mm 1520x3050mm 2050x3050mm Width(Max.): 2050mm Length(Max.): 5800mm | White, Black, Blue, Yellow, Green, Red, Grey |

| Customized size and color can be provided on request | |